Search This Supplers Products:Blanking lineSlitting lineFlying shearing lineScroll Cutting LineCut To Length LineRotary (oscillating) Shearing Line

- Home

- About us

- Products

- Automobile inner/outer board blanking device

- Shearing Line

- Tinplate & Aluminum Scroll Cutting Line

- Silicon Steel Shearing Line

- Duplex Slitter

- Slitter Machine

- Slitting Die / Tooling

- Press blanking line

- slitter line

- modular swing beam shear

- cleaner for pressing line

- blanking line

- cut to length line

- Slitting line

- Digital-controlled scroll cutting line

- Pinhole detector

- Scroll / Straight die

- Slitter

- Silicon-steel cross cutting line

- Faqs

- News

- Certificate

- Contact us

How to Improve the Quality of the Cross-cutting Line of Silicon Steel Sheet?

time2022/08/25

- If the silicon steel sheet shearing device is improperly operated and fails to meet the quality control indicators, it will increase the no-load current and no-load loss. Therefore, the standardized operation is very important.

The punching and shearing quality of the silicon steel sheet during the processing of the silicon steel sheet cross-cutting line, including punching and shearing dimensional accuracy, geometric shape, burr, degree of paint film damage, degree of bending and folding in the production process, etc., all directly affect the lamination coefficient, process coefficient, sheet gap air gap, etc.

If the operation is improper and the quality control index is not met, the no-load current and no-load loss will increase, and local overheating will occur in severe cases. The punching and shearing quality of silicon steel sheets is required to be very strict. Therefore, the selection of transformer core cross-cutting lines with high requirements for various indicators is also very strict.

In order to meet the requirements of various quality indicators, the cross-cutting line of silicon steel sheet must do the following:

1. The stacking of coils or sheets of silicon steel sheet cross-cutting line should be reasonable, and handling and hoisting should be handled lightly to prevent scratches, cracks, bending, or broken ends;

2. The sheet material after punching and shearing the cross-cutting line of the silicon steel sheet should be placed flat and neat, and the cutting edge should be sprayed with anti-rust paint;

3. When the burr of the cross-cutting line of the silicon steel sheet is too high, it is necessary to adjust the clearance of the tool and die in time, or regrind or replace the tool and die. equipment removal;

4. The individual bends of the cross-cutting line of the silicon steel sheet must be leveled and cannot be transferred to the next process;

5. The straightness, radian, and waviness of the silicon steel sheet cross-cutting line should be adjusted or removed during or before slitting. Correcting these on processing equipment is not possible;

6. Carefully adjust all aspects of processing equipment and molds so that their dimensional accuracy and burrs are within the range specified by the quality standards;

7. Pay attention to the rolling direction of the cross-cutting line of the silicon steel sheet when cutting the sheet material;

8. Strictly select films when pre-stacking, and pick out unqualified films;

9. The iron core structure and iron core should be reasonably designed to facilitate automatic punching, shearing, and stacking. Do not use threaded holes as much as possible;

10. It is necessary to use advanced tools and molds and advanced production lines as much as possible.

The above briefly introduces the methods that can improve the quality of the silicon steel sheet cross-cutting line. If you want to buy a silicon steel sheet shearing device, please contact us.

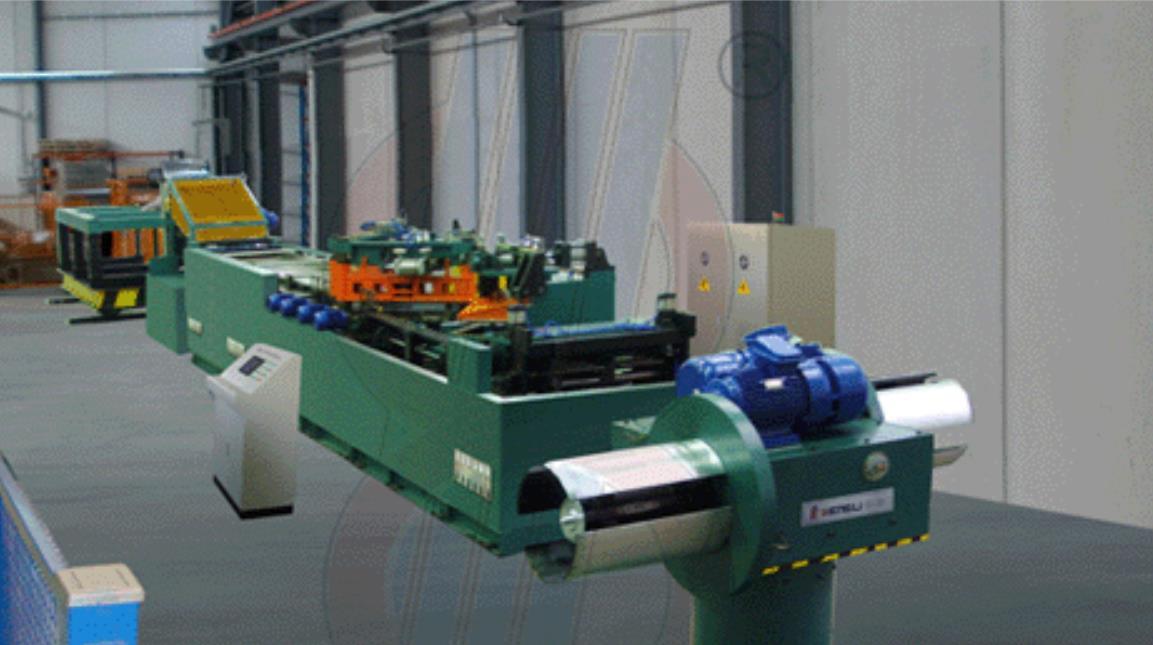

Hengli is a professional custom silicon steel sheet shearing devices manufacturer. The main products are: automotive outer panel stamping and forming automation systems, online robots, high-precision sheet metal automatic shearing devices, industrial automation online inspection systems, electrical automation devices, and automation control. Overall solution. The main products are synchronized with the world's advanced technology and are widely used in the pillar industries of the national economy such as automobile manufacturing and parts processing, iron and steel metallurgy processing, electric power, and metal packaging.