Search This Supplers Products:Blanking lineSlitting lineFlying shearing lineScroll Cutting LineCut To Length LineRotary (oscillating) Shearing Line

- Home

- About us

- Products

- Automobile inner/outer board blanking device

- Shearing Line

- Tinplate & Aluminum Scroll Cutting Line

- Silicon Steel Shearing Line

- Duplex Slitter

- Slitter Machine

- Slitting Die / Tooling

- Press blanking line

- slitter line

- modular swing beam shear

- cleaner for pressing line

- blanking line

- cut to length line

- Slitting line

- Digital-controlled scroll cutting line

- Pinhole detector

- Scroll / Straight die

- Slitter

- Silicon-steel cross cutting line

- Faqs

- News

- Certificate

- Contact us

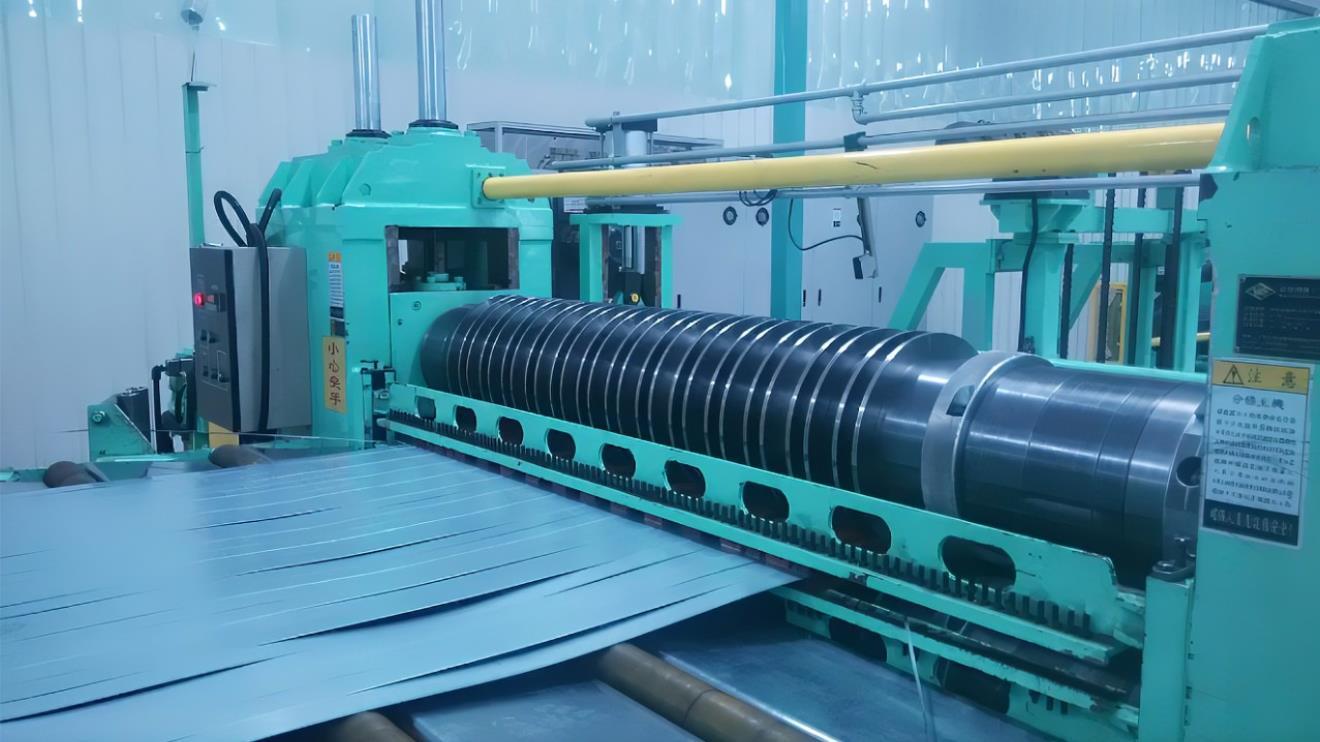

Analysis on the Future Development Direction of Metal Slitting Machine

time2022/09/02

- While the metal slitting machine is widely used, higher requirements are also put forward in terms of technology and performance. Continue reading to understand the future development direction of the metal slitting machine.

With the progress of society and the development of science and technology, the development of metal slitting machines is also facing great challenges, and higher requirements are also put forward in terms of technology and performance. What aspects should we consider to make a metal slitting machine tomorrow? What about better development? It should consider the following aspects.

First of all, we need to consider the frame structure of the slitting machine. Whether it is one-time slitting or two- or three-time slitting, slitting machine manufacturers should devote more energy to product research and development, study the frame structure, design More reasonable and advanced metal slitting machines, research and design more practical equipment that suits the needs of users, make the structure more precise when slitting different materials, and improve the competitiveness of its own products in the international market competition of slitting machines.

Secondly, we need to consider improving the automation and intelligence level of slitting machine control. So far, the automation level of metal slitting machines is a qualitative improvement compared with the level of the previous five years, but there is still a little gap compared with high-end brands, Although the use of the original control devices by most suppliers is very popular and the price is relatively low, there is still a certain gap in the depth of use of metal slitting machine manufacturers, especially in the control system and the metal slitting machine. The structure and the material to be cut lack organic combination.

The reason why the products produced by high-quality metal slitting machine manufacturers can be compared with the foreign high-end level is that these manufacturers can introduce high-end advanced technology, coupled with their own advanced production level and excellent technical research and development team, Most of the domestic metal slitting machines are still stuck on thick lines, and they have not fully understood the rigor and rationality of the metal slitting machine control system. Metal slitting machine manufacturers should start from the above directions and find a way to meet the principle of metal slitting machine control and slitting, and maximize the use of the functions provided by the hardware.

Finally, we have to consider the production and manufacture of slitting machines. In addition to being reasonable in design, any mechanical equipment also requires precision in manufacturing. In addition, the manufacturing process is also very important. Manufacturing slitting equipment, in addition to some general-purpose equipment In addition to the machine tools, there is also some special equipment for manufacturing metal slitting machines. Therefore, some equipment needs to use CNC machine tools to process parts, especially it is necessary to popularize the use of machining centers so that the equipment for metal slitting machines is manufactured. Machining accuracy can be fundamentally guaranteed.

As a professional custom sheet metal cutting equipment manufacturer. Hengli specializes in R&D and manufacturing high-end industrial automation equipment. The main products are synchronized with the world's advanced technology and are widely used in the pillar industries of the national economy such as automobile manufacturing and parts processing, iron and steel metallurgy processing, electric power, and metal packaging. The company aims to become a technology pioneer and market leader in the metal blanket forming industry, insist on innovation, build a brand, and prosper China's equipment manufacturing.