Search This Supplers Products:Blanking lineSlitting lineFlying shearing lineScroll Cutting LineCut To Length LineRotary (oscillating) Shearing Line

- Home

- About us

- Products

- Automobile inner/outer board blanking device

- Shearing Line

- Tinplate & Aluminum Scroll Cutting Line

- Silicon Steel Shearing Line

- Duplex Slitter

- Slitter Machine

- Slitting Die / Tooling

- Press blanking line

- slitter line

- modular swing beam shear

- cleaner for pressing line

- blanking line

- cut to length line

- Slitting line

- Digital-controlled scroll cutting line

- Pinhole detector

- Scroll / Straight die

- Slitter

- Silicon-steel cross cutting line

- Faqs

- News

- Certificate

- Contact us

How to Find a Sheet Metal Shearing Equipment Manufacturer?

time2023/05/25

- There are numerous manufacturers in the market, by following the steps outlined below, you can simplify your search and find the perfect sheet metal shearing equipment manufacturer.

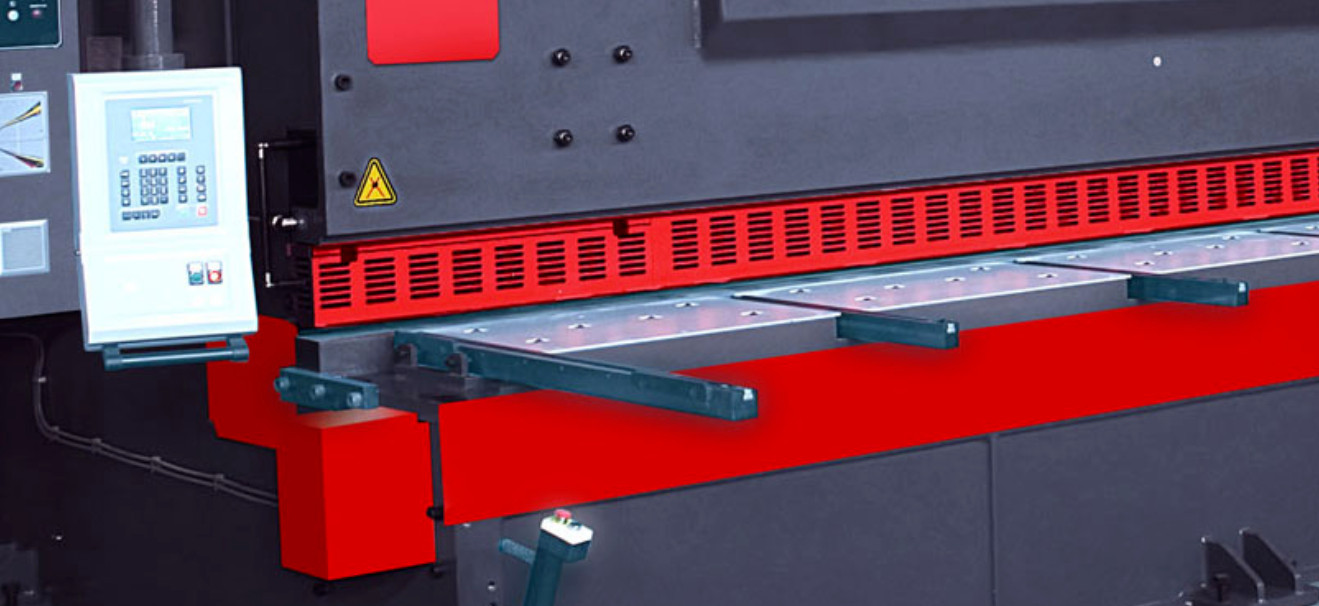

Sheet metal shearing involves cutting large sheets of metal into smaller, more manageable sizes. The process requires precision, speed, and accuracy, making it necessary to invest in reliable shearing equipment. However, with so many manufacturers on the market, it can be challenging to determine which one best suits your needs. By following the steps outlined below, you can simplify your search and find the perfect sheet metal shearing equipment manufacturer.

Understanding Sheet Metal Shearing Equipment

Sheet metal shearing is a metal fabrication process used to cut large sheets of metal into smaller sections or shapes. It involves applying shear to the metal, usually with a blade, to separate it along a specified cut line. The process is commonly used in industries such as automotive, construction, aerospace, and manufacturing.

Factors to Consider When Choosing a Manufacturer

When looking for a sheet metal shearing equipment manufacturer, it is crucial to consider several factors to make an informed decision. Here are some key areas to assess:

Equipment Quality

Look for a manufacturer that prioritizes equipment quality. The materials used, construction techniques, and overall construction should comply with industry standards. High-quality equipment will ensure durability, precision, and longevity.

Experience and Expertise

Consider a manufacturer with years of experience in the industry. They are more likely to have a solid understanding of the challenges and requirements of sheet metal shearing. Experienced manufacturers can also provide valuable insights and advice based on their expertise.

Custom Options

Every business has unique needs when it comes to sheet metal shearing equipment. Look for manufacturers that offer custom options to tailor equipment to your specific requirements. This may include features such as adjustable blade clearance, cutting angle control, or specialized tools.

Customer Support and Warranty

Reliable customer support is essential when investing in sheet metal shearing equipment. Choose a manufacturer that offers quality after-sales service, technical support, and timely assistance. Also, ask about the warranties their equipment offers to insure you against any manufacturing defects or malfunctions.

Research Sheet Metal Shearing Equipment Manufacturers

To find the right manufacturer, you need to do some in-depth research. Here are some effective approaches to consider:

Online Search and Catalog

Start by searching online for sheet metal shearing equipment manufacturers. Browse their websites to gather information about their products, services, and expertise. Also, take advantage of industry-specific directories and platforms that list well-known manufacturers.

Industry Trade Shows and Exhibitions

Attending industry trade shows is a great way to connect with multiple manufacturers in one place. These events provide the opportunity to see the equipment in person, interact with manufacturer representatives and discuss your specific requirements.

Referrals and Suggestions

Seek advice from industry professionals, colleagues, or business associates who have previously purchased sheet metal shearing equipment. Their first-hand experience and insights can help you narrow down your options and find a manufacturer with a proven track record.

Compare Pricing and Cost Benefits

While pricing should not be the only determining factor, it is important to evaluate the cost-effectiveness of the equipment. Consider the following aspects:

Initial Cost vs. Long-Term Value

Assess the initial cost of the equipment and compare it to the long-term value it provides. A higher upfront investment may be required if the equipment provides superior performance, durability, and productivity gains over the long term.

Additional Features and Functionality

Compare features and functionality offered by different manufacturers. Look for value-added features that increase productivity, enhance safety, or provide extra versatility during shearing.

Maintenance and Operating Costs

Consider the maintenance and operating costs associated with the equipment. Manufacturers who provide systems that are efficient and easy to maintain can save you time and money in the long run.

Make a Final Decision

Once you've gathered all the necessary information and evaluated different manufacturers, it's time to make a final decision. In these order:

Screen Potential Manufacturers

Based on your research and evaluation, create a shortlist of manufacturers who meet your criteria in terms of quality, customization options, customer support, and reputation.

Request a Quote and Advice

Contact shortlisted manufacturers for a quote and advice on the specific sheet metal shearing equipment you need. Compare quotes and consider the overall value they offer, taking into account factors such as quality, customization, and after-sales support.

Tour Facilities and Evaluate Equipment

If possible, schedule a tour of the facilities of the top manufacturers on your list. This will give you the opportunity to see their equipment in person, evaluate their manufacturing process, and discuss your requirements in detail with their experts. It also allows you to assess the overall professionalism and competence of the manufacturer.

In Conclusion

Finding the right sheet metal shearing equipment manufacturer is critical to the success of your business. By considering factors such as quality, customization options, customer support, and reputation, you can make an informed decision. Thorough research, evaluations, and comparisons will help you identify a manufacturer that not only offers high-quality equipment but also provides the necessary support and service for a seamless experience. Remember, investing in reliable and efficient sheet metal shearing equipment can significantly increase your productivity, accuracy, and overall efficiency, thereby increasing the profitability of your business. If you are looking for a sheet metal shearing equipment manufacturer, welcome to contact us.

HENGLI is a professional custom sheet metal shearing equipment manufacturer. The main products are sheet metal shearing devices, automotive outer panel stamping and forming automation systems, online robots, high-precision sheet metal automatic shearing devices, industrial automation online detection systems, electrical automation Devices, and automation control overall solutions. The main products are synchronized with the world's advanced technology, and are widely used in the pillar industries of the national economy such as automobile manufacturing and parts processing, iron and steel metallurgical processing, electric power, and metal packaging.