Search This Supplers Products:Blanking lineSlitting lineFlying shearing lineScroll Cutting LineCut To Length LineRotary (oscillating) Shearing Line

- Home

- About us

- Products

- Automobile inner/outer board blanking device

- Shearing Line

- Tinplate & Aluminum Scroll Cutting Line

- Silicon Steel Shearing Line

- Duplex Slitter

- Slitter Machine

- Slitting Die / Tooling

- Press blanking line

- slitter line

- modular swing beam shear

- cleaner for pressing line

- blanking line

- cut to length line

- Slitting line

- Digital-controlled scroll cutting line

- Pinhole detector

- Scroll / Straight die

- Slitter

- Silicon-steel cross cutting line

- Faqs

- News

- Certificate

- Contact us

What Types of Slitting Lines Are There?

time2023/07/03

- There are different types of slitting lines available, each designed to meet specific needs and requirements. In this article, we will explore the various types of slitting lines and their characteristics.

Slitting lines are vital in the metalworking industry because of their ability to efficiently cut and slit metal coils into narrower strips. These strips are used in various industries including automotive, construction, and manufacturing. There are different types of slitting lines available, each designed to meet specific needs and requirements. In this article, we will explore the various types of slitting lines and their characteristics.

1. Basic Slitting Line

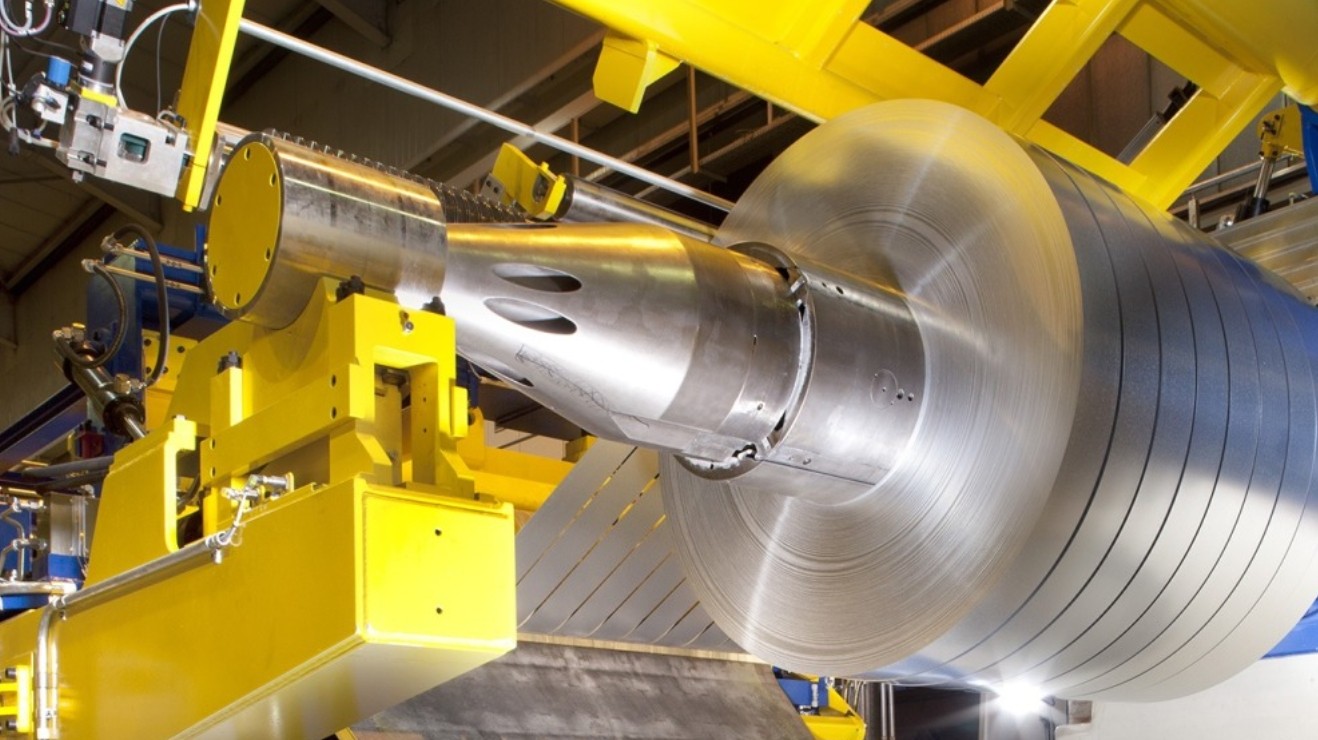

Basic slitting lines are the most common and simplest type. It consists of uncoiler, slitter, and winder. Metal coils are uncoiled from an uncoiled, passed through a slitter, and rewound onto a recoiler. This type of slitting line is suitable for general purposes and is widely used in metal processing facilities.

2. Cycle Slitting Line

The circulating slitting line adopts a circulating pit or circulating control system, which can run continuously without interrupting the material flow. The circulation pit acts as a buffer to ensure smooth and continuous feeding of metal coils. This type of slitting line is ideal for high-speed processing and can handle large-size coils.

3. Tension Slitting Line

Tension slitting lines utilize a tension control mechanism to maintain consistent tension throughout the slitting process. This ensures precise cutting of the metal coil. Tension slitting lines are often used when dealing with sensitive materials or when tight tolerances are required.

4. Combined Slitting Line

Combination slitting lines combine the functionality of a slitting line with other processes such as cutting to length or recoiling. This versatility can increase the efficiency and productivity of metalworking operations. Combination slitting lines are ideal for facilities requiring multiple processing capabilities on a single line.

5. High-Speed Slitting Line

High-speed slitting lines are designed for maximum productivity and efficiency. They are equipped with advanced automation and control systems to handle the high-speed processing of metal coils. Capable of handling large volumes of material, these lines are often used in industries with demanding production requirements.

6. Packing Slitting Line

Slitting lines with wrapping feature integrate additional equipment for efficient wrapping of slit strips. This includes stacking, bundling, and packing systems. These lines are ideal for applications that require direct packaging and shipping of slit tape for further processing or shipping.

7. Special Material Slitting Production Line

Certain materials require dedicated slitting lines to ensure optimal processing. For example, stainless steel, aluminum, or other non-ferrous metals may require slitting lines with specific features to prevent surface damage or contamination. These specialized lines are designed to handle the unique characteristics of this type of material.

8. Precision Slitting Line

Precision slitting lines are designed for high precision and tight tolerances in slitting operations. These lines employ advanced technology and sophisticated control systems to ensure consistent strip width and edge quality. Precision slitting lines are often used in industries where precision is critical, such as electronics and automotive manufacturing.

9. Large Size Slitting Line

Large format slitting lines are specially designed to handle thick and heavy metal coils. These lines are equipped with robust components and powerful slitting units capable of cutting thick materials. Heavy-gauge slitting lines are suitable for industries that require the processing of thick-gauge metal strips, such as shipbuilding and structural steel fabrication.

10. Automatic Slitting Line

Automated slitting lines utilize advanced automation systems to optimize the slitting process. These lines feature automatic coil loading, slit strip measurement, and coil unloading. Automation increases productivity, reduces human intervention, and ensures consistent quality throughout operations.

11. Reverse Slitting Line

Reverse slitting lines are used when the slitting strip needs to be wound in the opposite direction compared to conventional methods. This type of slitting line is suitable for applications where the end user requires the strip to be wound in a specific way, such as rewinding applications or further processing requirements.

12. Non-metal Slitting Line

While slitting lines are usually associated with metalworking, there are also slitting lines designed for non-metallic materials. These lines are used to cut materials such as paper, plastic film, textiles, etc. Non-metallic slitting lines are available to meet the specific requirements of these materials, ensuring clean and precise cuts.

13. Strip Slitting Line

Thin strip slitting lines are specially designed for processing narrow and thin metal strips. These lines are designed to handle delicate materials without damage or deformation. They often incorporate features such as non-contact tension control and ultra-precise slitting devices to maintain the integrity of thin strips.

In Conclusion

Slitting lines play a vital role in the metal processing industry, efficiently cutting and slitting metal coils into narrower strips. There are several types of slitting lines to choose from, each designed to meet specific needs and requirements. From basic slitting lines to high-speed automated systems, the choice depends on the nature of the material, required precision, throughput, and other factors. By choosing the right type of slitting line, metalworking equipment can increase productivity, precision, and overall efficiency.

The above introduces the types of slitting wires, if you want to buy slitting wires, please contact us.

HENGLI is a professional custom slitting line manufacturer. Our company has more than 10 innovation patents and nearly 30 utility creation patents. As one of the national industry standard-setting members, we have core technologies and core products with independent intellectual property rights. The main products are synchronized with the world's advanced technology and are widely used in the pillar industries of the national economy such as automobile manufacturing and parts processing, iron and steel metallurgical processing, electric power, and metal packaging.