Search This Supplers Products:Blanking lineSlitting lineFlying shearing lineScroll Cutting LineCut To Length LineRotary (oscillating) Shearing Line

- Home

- About us

- Products

- Automobile inner/outer board blanking device

- Shearing Line

- Tinplate & Aluminum Scroll Cutting Line

- Silicon Steel Shearing Line

- Duplex Slitter

- Slitter Machine

- Slitting Die / Tooling

- Press blanking line

- slitter line

- modular swing beam shear

- cleaner for pressing line

- blanking line

- cut to length line

- Slitting line

- Digital-controlled scroll cutting line

- Pinhole detector

- Scroll / Straight die

- Slitter

- Silicon-steel cross cutting line

- Faqs

- News

- Certificate

- Contact us

How a Coil Straightener Can Transform Your Metalworking Process

time2024/08/10

- Coil straighteners can significantly impact every aspect of the metalworking process, and this guide explores how a coil straightener can revolutionize your metalworking operation.

In metal processing, precision and efficiency are crucial. Coil straighteners (also known as coil levelers or levelers) play a vital role in improving the quality and consistency of metal products. By processing rolls of metal into flat, uniform sheets, these machines can significantly impact every aspect of the metalworking process. This guide explores how coil straighteners can revolutionize your metalworking operation, highlighting their benefits, applications, and best practices.

What is a Coil Straightener?

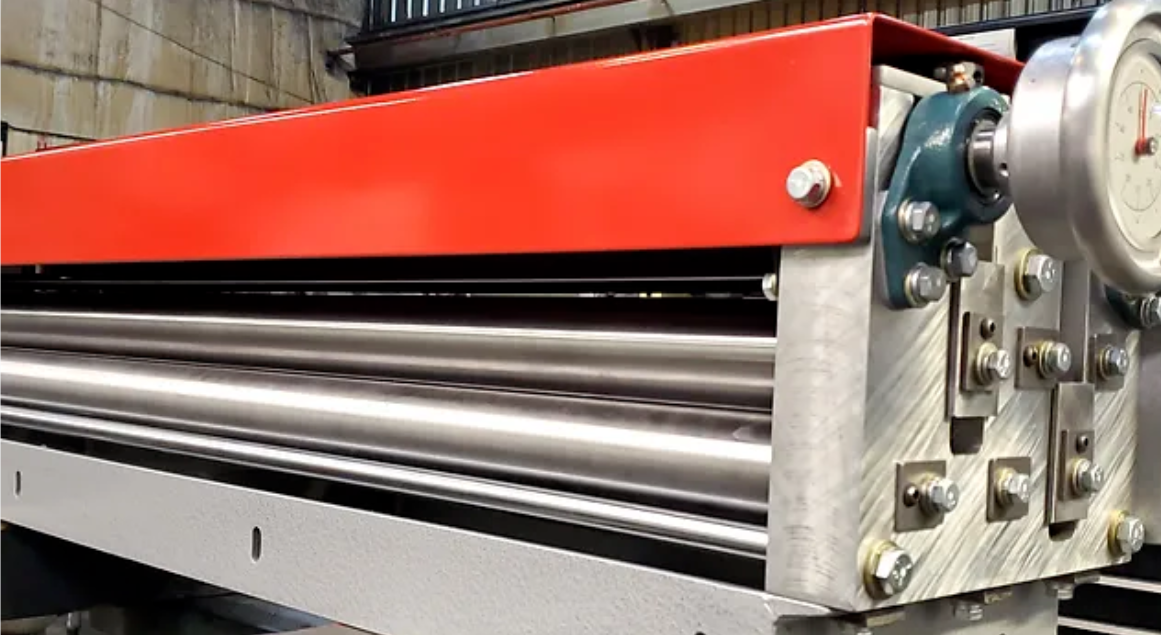

A coil straightener is a machine used to straighten metal sheets rolled into rolls, eliminating bends, twists or deformations. It consists of a series of rollers and guides that gradually straighten the metal as it passes through the machine.

Coil Straightener Ingredients

· Feed roller: pulls the coil into the machine and guides it through the straightening process.

· Straightening Rollers: A series of rollers that apply pressure to correct bends and twists.

· Control system: adjusts the alignment and pressure of the drum to achieve optimal straightening results.

Benefits of Using a Coil Straightener

Coil straighteners are essential tools in metal processing that can improve the quality and efficiency of metal processing. The four main benefits of using a coil straightener are detailed below:

1. Improve Metal Flatness

One of the primary functions of a coil straightener is to straighten metal sheets rolled into rolls, eliminating any bends, twists, or deformations. This straightening process is critical to achieving consistent metal quality and ensuring the final product meets precise specifications.

- Consistent quality: By eliminating distortion and ensuring uniform flatness, coil straighteners help maintain high-quality standards of finished metal. This is especially important for applications requiring precise dimensions and smooth surfaces.

- Defect reduction: Metal sheets that are not flattened correctly can lead to defects in the final product, such as misalignment or poor fit. Flattened metal reduces the occurrence of such defects, thereby improving overall product quality.

2. Improve Precision and Accuracy

Coil straighteners provide precise control of the straightening process, achieving tight tolerances and accurate measurements. This accuracy is critical for applications where precise dimensions are critical.

- Tight tolerances: Coil straighteners enable metal workers to achieve tight tolerances, ensuring each sheet of metal meets precise specifications. This kind of precision is critical for components that must fit perfectly or perform a specific function.

- Precise Measurements: Precise straightening ensures reliable and consistent measurements from sheet metal, which is critical for quality control and production efficiency.

3. Improve Production Efficiency

By automating the straightening process, coil straighteners significantly increase production efficiency. This automation reduces the time and labor required to obtain flat metal sheets, thereby shortening production cycles.

- Faster processing: The coil straightener simplifies the metal flattening process, allowing faster handling and processing of metal sheets. Increased speed helps increase productivity and shorten lead times.

- Reduced labor: Automation reduces the need for manual intervention during the straightening process, allowing workers to focus on other tasks and improving overall operational efficiency.

4. Cost Savings

Using a coil straightener can result in cost savings in multiple areas, including material utilization, labor, and overall production costs.

Reduce material waste: Properly straightened metal sheets have fewer defects and are less likely to be discarded due to defects. Improved material utilization can save raw material costs.

- Reduced labor costs: By automating the straightening process, coil straighteners reduce the need for labor, which can reduce labor costs and increase overall productivity.

- Long-term savings: Investing in a coil straightener can bring long-term savings through increased efficiency, reduced defects and improved material utilization, ultimately helping to achieve a more cost-effective production process.

Application of Coil Straightener

1. Automobile Industry

Auto parts require precise dimensions and smooth surfaces to fit and function properly. Coil straighteners remove any distortion in sheet metal, ensuring parts are properly aligned and functioning as expected. This is critical to vehicle safety and performance.

Automating the straightening process with a coil straightener increases production efficiency, speeds metal preparation and reduces manual labor. This helps automakers meet high production volumes and tight deadlines. Additionally, consistently flat sheet metal improves part quality, reduces defects and increases overall vehicle reliability. Adhering to strict quality standards is critical to compliance and customer satisfaction in the automotive industry.

2. Construction Industry

Metal panels used in construction, such as beams and columns, must be completely flat to ensure proper assembly and load-bearing capacity. Coil straighteners help achieve this flatness, ensuring that structural components meet engineering specifications. In addition to functionality, construction projects often require metal components that look great.

Straightened metal sheets help achieve a smoother surface and cleaner appearance, thereby enhancing the overall aesthetics of buildings and infrastructure. Coil straighteners simplify the preparation of architectural metal panels, reducing processing time and improving overall workflow. This efficiency helps complete construction projects on time and helps manage project costs.

3. Manufacturing

Manufacturers use coil straighteners to produce custom parts and sheet metal that require precise dimensions and a flat surface. This is important to ensure the parts fit accurately and function as expected in the finished product. Straightened sheet metal reduces the likelihood of defects in the final product, such as misalignment or a poor fit.

This improves quality standards and reduces rework or scrap, helping to save costs and increase efficiency. Coil straighteners are available for a variety of metal types and thicknesses, allowing manufacturers to meet different production needs. This versatility supports the manufacture of products ranging from industrial machinery to everyday consumer products.

Conclusion

Coil straighteners are a game-changing tool for the metalworking industry, providing increased accuracy, increased efficiency and cost savings. By understanding its benefits, applications, and best practices, you can leverage coil straighteners to improve your metalworking processes and achieve superior results. Investing in the right coil straightener and implementing best practices will help you streamline your operations and provide high-quality metal products.

Hengli is a professional coil straightening equipment manufacturer led by innovation and cutting-edge technology. Its main product series are seamlessly connected with the world's advanced technology and are widely used in automobile manufacturing and parts processing, steel metallurgical processing, electric power, metal packaging, etc. key areas of the national economy.

With the vision of becoming a pioneer in the metal felt molding industry, Hengli is unswervingly committed to innovation and brand building to promote the prosperity and development of China's equipment manufacturing industry. Hengli puts innovation first, unswervingly focuses on technological progress, strives to become a technology pioneer and market leader, promotes the progress of China's equipment manufacturing industry, and at the same time sets new standards for quality and performance in the global market. If you are looking for a reliable coil straightener, please contact us.

FAQ

1. What types of metals can the coil straightener process?

Coil straighteners can process a variety of metals, including steel, aluminum and stainless steel. Make sure to choose a machine that is compatible with the specific type of metal you want to process.

2. How often does the coil straightener need maintenance?

Regular maintenance is essential for optimal performance. Follow the manufacturer's recommended maintenance intervals and perform routine inspections to ensure your machine remains in good condition.

3. Can the coil straightener handle metals of different thicknesses and widths?

Yes, many coil straighteners are designed to handle a variety of thicknesses and widths. Choose a machine that meets the specifications of the sheet metal you plan to process.

4. What impact does using a coil straightener have on production costs?

Using a coil straightener can significantly save production costs by reducing material waste, lowering labor costs, and improving overall efficiency.

5. How do I choose a coil straightener that suits my needs?

Consider factors such as metal type, thickness and width requirements, and the degree of automation required. Additionally, look for machines with reliable support and maintenance services to ensure long-term performance.