Search This Supplers Products:Blanking lineSlitting lineFlying shearing lineScroll Cutting LineCut To Length LineRotary (oscillating) Shearing Line

- Home

- About us

- Products

- Automobile inner/outer board blanking device

- Shearing Line

- Tinplate & Aluminum Scroll Cutting Line

- Silicon Steel Shearing Line

- Duplex Slitter

- Slitter Machine

- Slitting Die / Tooling

- Press blanking line

- slitter line

- modular swing beam shear

- cleaner for pressing line

- blanking line

- cut to length line

- Slitting line

- Digital-controlled scroll cutting line

- Pinhole detector

- Scroll / Straight die

- Slitter

- Silicon-steel cross cutting line

- Faqs

- News

- Certificate

- Contact us

Unlocking Efficiency: How Metal Scroll Cutting Lines Revolutionize Manufacturing

time2024/11/20

- Discover how Hengli's advanced metal scroll cutting lines are transforming manufacturing efficiency, reducing waste, and increasing productivity.

In the ever-evolving landscape of manufacturing, efficiency is paramount. As industries strive to streamline operations and reduce costs, metal scroll cutting lines have emerged as a transformative solution. At Hengli, we are at the forefront of this revolution, providing cutting-edge technology that enhances productivity and optimizes material usage. This article delves into the intricacies of metal scroll cutting lines, their benefits, and how they are reshaping the manufacturing sector.

Understanding Metal Scroll Cutting Technology

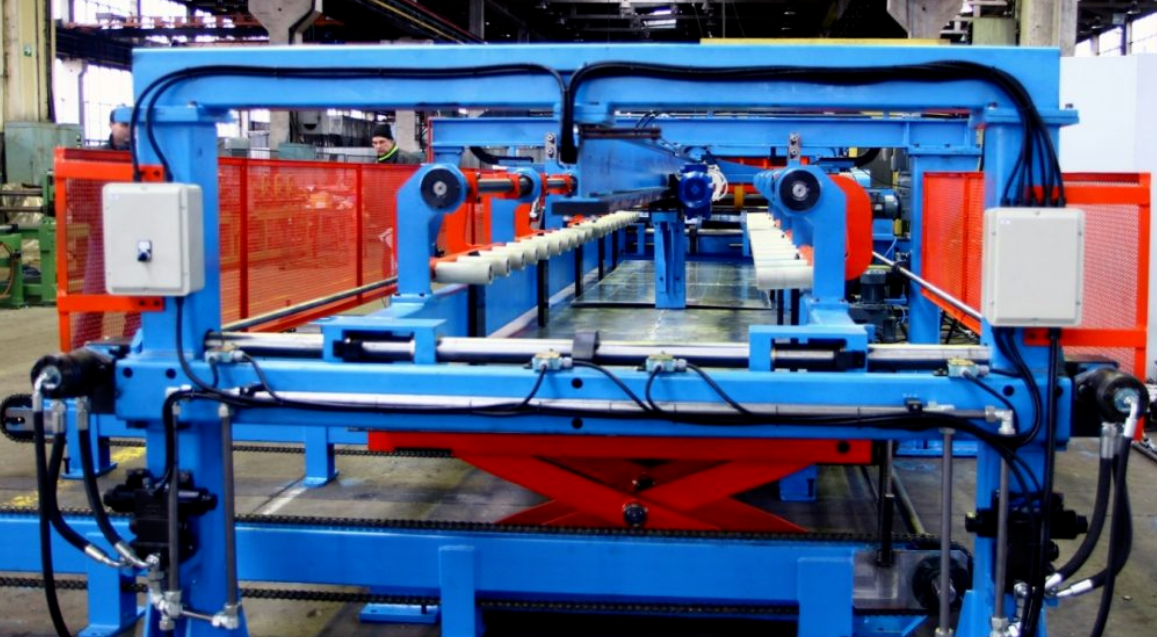

Metal scroll cutting lines are specialized machines designed for the precise cutting of metal sheets into intricate shapes and forms. Utilizing advanced CNC (Computer Numerical Control) technology, these cutting lines ensure accuracy and repeatability, significantly reducing the likelihood of human error. The scroll-cutting process involves a series of automated steps, including feeding, cutting, and unloading, which collectively enhance operational efficiency.

Key Components of Metal Scroll Cutting Lines

Feeding System: An automated feeding system is crucial for maintaining a steady flow of material into the cutting area. This system minimizes downtime and ensures that production runs smoothly.

Cutting Mechanism: At the heart of the scroll cutting line, the cutting mechanism employs high-speed blades or lasers that can handle various thicknesses and types of metal, from aluminum to stainless steel.

Control Panel: Equipped with user-friendly interfaces, the control panel allows operators to program cutting patterns and monitor the machine's performance in real time.

Unloading System: After cutting, the unloading system efficiently removes finished products from the cutting area, readying the machine for the next cycle.

Benefits of Metal Scroll Cutting Lines

1. Enhanced Efficiency and Speed

One of the most significant advantages of metal scroll cutting lines is their ability to operate at high speeds without compromising precision. Traditional cutting methods often involve manual labor, which can be slow and prone to errors. In contrast, Hengli's automated systems can execute complex cuts swiftly, drastically reducing production times.

2. Cost Reduction

By minimizing material waste and maximizing output, metal scroll-cutting lines contribute to substantial cost savings. The precision of the cutting process ensures that every piece of metal is utilized effectively, reducing excess scrap and lowering raw material costs.

3. Versatility in Applications

Metal scroll cutting lines are incredibly versatile, capable of handling various materials and producing a wide range of products. From automotive parts to decorative metalwork, the applications are extensive. This adaptability allows manufacturers to diversify their product offerings and respond swiftly to market demands.

4. Improved Safety Standards

Automated cutting lines enhance workplace safety by reducing the need for manual intervention. With advanced safety features, including emergency stop buttons and protective barriers, the risk of accidents is significantly diminished, fostering a safer working environment.

5. High-Quality Output

Hengli's metal scroll cutting lines are designed to deliver consistent, high-quality results. Precision cutting ensures that each piece meets stringent quality standards, which is crucial in industries where tolerances are critical.

Implementing Metal Scroll Cutting Lines in Your Facility

1. Assessing Your Needs

Before integrating a metal scroll cutting line into your manufacturing process, it's essential to assess your specific needs. Consider factors such as production volume, types of materials, and desired output quality. This evaluation will guide you in selecting the right equipment for your operations.

2. Choosing the Right Equipment

At Hengli, we offer a range of metal scroll-cutting lines tailored to various industrial applications. Our team of experts can assist you in selecting the optimal solution that aligns with your production goals and budget.

3. Training and Support

Successful implementation of new technology requires proper training for your staff. Hengli provides comprehensive training programs to ensure that your team can operate the equipment efficiently and safely. Additionally, our ongoing support ensures that any issues are addressed promptly, minimizing downtime.

The Future of Metal Scroll Cutting Technology

As technology continues to advance, the future of metal scroll cutting lines looks promising. Innovations such as AI integration, IoT connectivity, and enhanced automation are set to further revolutionize manufacturing processes. Hengli is committed to staying at the forefront of these developments, continually improving our offerings to meet the evolving needs of our customers.

Conclusion

In conclusion, metal scroll cutting lines represent a significant leap forward in manufacturing efficiency. By investing in Hengli's advanced solutions, businesses can unlock new levels of productivity, reduce costs, and enhance product quality. As industries continue to embrace automation, those who adopt these innovative technologies will undoubtedly gain a competitive edge in the market.

As a professional metal scroll cutting lines manufacturer, Hengli focuses on the manufacturing of high-end industrial automation equipment. Its main products are world-leading in technology and are widely used in pillar industries of the national economy such as automobile manufacturing and parts processing, steel metallurgy processing, electricity, and metal packaging. The company is determined to become a technological pioneer and market leader in the metal carpet molding industry, adhere to innovation, build brands, and revitalize my country's equipment manufacturing industry.

For more information on how Hengli can transform your manufacturing operations, contact us today to discuss your specific needs and explore our range of cutting-edge products.