Search This Supplers Products:Blanking lineSlitting lineFlying shearing lineScroll Cutting LineCut To Length LineRotary (oscillating) Shearing Line

- Home

- About us

- Products

- Automobile inner/outer board blanking device

- Shearing Line

- Tinplate & Aluminum Scroll Cutting Line

- Silicon Steel Shearing Line

- Duplex Slitter

- Slitter Machine

- Slitting Die / Tooling

- Press blanking line

- slitter line

- modular swing beam shear

- cleaner for pressing line

- blanking line

- cut to length line

- Slitting line

- Digital-controlled scroll cutting line

- Pinhole detector

- Scroll / Straight die

- Slitter

- Silicon-steel cross cutting line

- Faqs

- News

- Certificate

- Contact us

Duplex Slitter vs. Single Blade: Which Is Right for Your Factory?

time2025/07/03

- Get a comprehensive comparison of double edge vs. single edge slitters. Learn which cutting technology can deliver the productivity, precision, and cost-effectiveness you need for your manufacturing needs.

In the rapidly evolving landscape of industrial manufacturing, precision, efficiency, and versatility are critical factors that determine the success of your production line. When selecting slitting machinery, understanding the fundamental differences between duplex slitters and single blade slitters is essential. This comprehensive guide provides an in-depth analysis of both technologies, helping manufacturers make informed decisions tailored to their specific operational needs. At Hengli, we leverage decades of expertise to deliver cutting-edge slitting solutions designed to optimize your manufacturing processes.

Understanding Slitting Technology: An Overview

Slitting is a crucial process in converting large rolls of material into narrower strips, facilitating easier handling, storage, and further processing. The core of this process lies in the slitter machines, which are engineered to cut materials such as metal sheets, plastic films, paper, and foils with high precision.

Two primary types of slitter machines dominate the industry:

Single Blade Slitters

Duplex Slitters

Each type offers distinct advantages and limitations, making them suitable for different applications and production scales.

What Is a Single-Blade Slitter?

A single-blade slitter features one cutting blade that performs the slitting operation. The material roll is fed through the machine, where the blade slices the material into multiple strips simultaneously or sequentially.

Key Features of Single-Blade Slitters

Simplicity of Design: Fewer components lead to easier maintenance and setup.

Cost-Effectiveness: Generally lower initial investment, making them suitable for small to medium-scale operations.

Versatility: Capable of handling a wide range of materials and thicknesses.

High Precision: Equipped with adjustable blades to achieve tight tolerances.

Applications of Single Blade Slitters

Paper and cardboard manufacturing

Plastic film production

Thin metal sheet processing

Flexible packaging materials

Limitations of Single Blade Slitters

Slower production speeds compared to duplex slitters

Limited throughput capacity for high-volume operations

Potential for increased blade wear when cutting thicker or harder materials

What Is a Duplex Slitter?

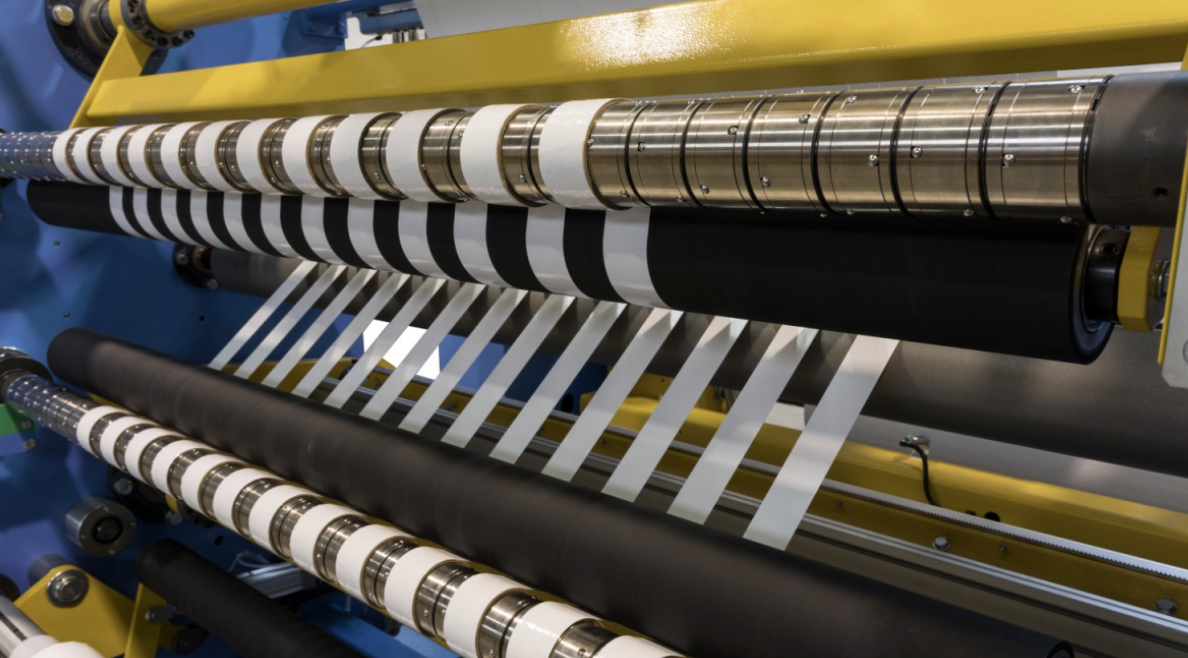

A duplex slitter incorporates dual cutting blades that operate either simultaneously or alternately to perform slitting tasks. This configuration enables higher efficiency and greater flexibility in production.

Key Features of Duplex Slitters

Dual Blades: Allow for parallel processing of material, significantly increasing throughput.

Enhanced Automation: Often equipped with advanced control systems for precise blade synchronization.

Improved Material Handling: Capable of processing thicker and more complex materials with consistent quality.

Reduced Downtime: The dual-blade setup facilitates faster changeovers and maintenance.

Applications of Duplex Slitters

Heavy-gauge metal sheets

Large-volume plastic film production

Complex multi-layered materials

High-speed industrial manufacturing

Limitations of Duplex Slitters

Higher initial cost due to complex design

More maintenance requirements to ensure dual blades operate harmoniously

Larger footprint necessitating more space in the factory

Comparative Analysis: Duplex Slitter vs. Single Blade

1. Production Speed and Throughput

Duplex slitters excel in high-volume production environments due to their ability to process multiple strips simultaneously. They significantly reduce cycle times, enabling factories to meet tight deadlines and large order volumes.

In contrast, single-blade slitters are more suited for lower throughput applications, where flexibility and cost are more critical than speed.

2. Flexibility and Material Compatibility

Single blade slitters offer greater flexibility for a wide range of materials and thicknesses, making them ideal for customized or small-batch production.

Duplex slitters are better suited for standardized, high-volume materials, especially when handling thicker or more complex materials that benefit from simultaneous dual cuts.

3. Cost and Investment

Initial investment in duplex slitters is significantly higher due to their complex design and automation features. However, the cost per unit decreases over time with increased throughput.

Single blade slitters are more affordable upfront, making them a cost-effective solution for startups or factories with limited budgets.

4. Maintenance and Operational Complexity

Single blade slitters are easier to maintain and operate, requiring less technical expertise.

Duplex slitters demand more rigorous maintenance protocols and skilled operators to ensure dual blades operate in harmony without compromising precision.

5. Precision and Quality

Both machines can achieve high levels of precision, but duplex slitters often feature advanced control systems that facilitate more consistent cuts across high-speed operations.

Hengli integrates state-of-the-art sensors and automation to maximize precision in both machine types.

Choosing the Right Slitter for Your Factory: Key Considerations

Production Volume and Speed Requirements

For small to medium production runs or customized cuts, single blade slitters are ideal.

For large-scale, high-volume manufacturing, duplex slitters provide the necessary speed and efficiency.

Material Type and Thickness

Thin, flexible materials are well-suited for single blade slitters.

Thicker or more complex materials benefit from duplex slitters' ability to handle higher stresses.

Budget Constraints

Initial investment plays a significant role. Single blade slitters are more cost-effective.

Consider long-term savings through higher throughput with duplex slitters if your production demands justify the expense.

Operational Complexity and Maintenance

If your factory prefers simpler operation and maintenance, single blade slitters are preferable.

For automated, high-speed production, duplex slitters equipped with advanced control systems are better.

Future Expansion and Flexibility

Assess growth plans. Investing in duplex slitters may provide scalability for future demands.

Why Choose Hengli for Your Slitting Needs?

At Hengli, we are committed to delivering innovative, reliable, and efficient slitting solutions tailored to your specific manufacturing needs. Our duplex and single blade slitters are engineered with cutting-edge technology, ensuring precision, durability, and ease of operation.

Hengli’s customizable configurations allow us to provide machines optimized for your material types and production volume, ensuring maximum efficiency and cost savings. Our dedicated team of engineers offers comprehensive support from installation to maintenance, guaranteeing minimal downtime and optimal performance.

Conclusion: Making the Right Choice for Your Factory

The decision between duplex slitters and single blade slitters hinges on your factory’s specific operational needs, budget, and long-term growth plans. While single blade slitters excel in cost-effective, flexible, and smaller-scale applications, duplex slitters are indispensable for high-speed, high-volume, and complex manufacturing environments.

Hengli stands ready to guide your factory through this vital choice, offering industry-leading slitting solutions that enhance productivity, precision, and profitability. By understanding the distinct advantages and limitations of each machine type, your factory can maximize operational efficiency and maintain a competitive edge in the marketplace.

Contact Hengli Today for Expert Consultation and Custom Slitting Solutions

Elevate your manufacturing process with Hengli’s advanced slitting technology. Reach out to our industry experts for a personalized assessment and discover how our duplex and single blade slitters can transform your factory’s productivity.

For can-making company to vertically and horizontally slit tinplate precisely.